I-Yc-8701a etywiniweyo engangeni manzi e-Nano-composite Ceramic coating

Izixhobo zemveliso kunye nenkangeleko

(Ukwambathisa i-ceramic enecandelo elinye

Ulwelo olungenambala ukuya kolutyheli obukhanyayo

Imibala ye-YC-8701: ecacileyo, ebomvu, emthubi, eluhlaza okwesibhakabhaka, emhlophe, njl. Ukulungiswa kombala kungenziwa ngokweemfuno zabathengi

Isiseko esisebenzayo

Intsimbi engeyiyo ikhabhoni, intsimbi engatyiwayo, intsimbi ephosiweyo, i-titanium alloy, i-aluminium alloy, i-copper alloy, iglasi, iiseramikhi, ilitye lokwenziwa, igypsum, ikhonkrithi, ifayibha yeseramikhi, umthi, njl.njl.

Ubushushu obusebenzayo

Uluhlu lobushushu bokusebenza oluhlala ixesha elide: -50℃ ukuya kwi-200℃.

Ukumelana nobushushu kwengubo kuya kwahluka ngokuxhomekeke kukumelana nobushushu bezinto ezahlukeneyo. Iyamelana nokubanda kunye nobushushu kunye nokungcangcazela kobushushu.

Iimpawu zemveliso

Iingubo zeNano ziyinxalenye enye, zinobuhlobo nokusingqongileyo, azinatyhefu, kulula ukuzisebenzisa kwaye zisebenza kakuhle.

2. Ingubo iphumelele uvavanyo lwe-SGS kunye novavanyo lwe-FDA eMelika, kwaye ikumgangatho wokutya.

3. I-nano-coating inokungena okunamandla kakhulu. Ngokungena, ukugquma, ukuzalisa, ukutywina kunye nokwakheka kwefilimu yomphezulu, inokufezekisa ukusebenza okuzinzileyo nangokufanelekileyo kokuvala kunye nokungangeni manzi.

Ubunzima bokugquma bunokufikelela kwi-6 ukuya kwi-7H, nto leyo ekwaziyo ukumelana nokuguguleka, ukuhlala ixesha elide, ukumelana ne-asidi kunye ne-alkali, ukumelana nokugqwala, ukumelana nokutshizwa ngetyuwa, kunye nokulwa nokwaluphala. Ingasetyenziswa ngaphandle okanye kwiimeko zokusebenza ezinomswakama ophezulu kunye nobushushu obuphezulu.

5. Ingubo inamathela kakuhle kwi-substrate, inamandla okubopha angaphezu kwe-5 MPa.

6. I-nano-inorganic composite coating ine-insulation egqwesileyo yombane.

7. Ingubo ngokwayo ayitshi kwaye ineempawu ezithile ezithintela umlilo.

8. Ingubo ayimelani nokubanda nobushushu obuphezulu kwaye inokumelana kakuhle nobushushu.

9. Eminye imibala okanye ezinye iimpawu zingalungiswa ngokweemfuno zabathengi.

Amasimi esicelo

1. Iipayipi, izibane, izitya, igrafayithi.

2. Ukuthintela amanzi ngokufanelekileyo kwiindawo zokuhlambela okanye kwiikhikhini, kwiisinki okanye kwiitonela, njl.njl.

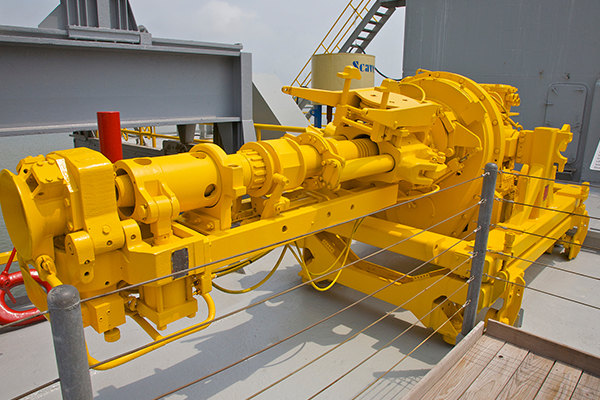

3. Iindawo ezingaphantsi kwamanzi (ezilungelelaniswe namanzi olwandle), iinqanawa, iinqanawa, njl.njl.

4. Izinto zokuhombisa izakhiwo, izinto zokuhombisa zefenitshala.

5. Ukuqinisa nokuphucula iimpawu zokulwa nokugqwala kwe-bamboo kunye neenkuni.

Indlela yokusetyenziswa

1. Ukulungiselela ngaphambi kokugquma

Ukuhluzwa kwepeyinti: Hlunga ngesikrini sesihluzo se-400-mesh uze ubeke ecaleni emva kokuhluzwa.

Ukucoca izinto ezisisiseko: Ukususa amafutha kunye nokugqwala, ukurhawuzelela umphezulu kunye nokuqhumisa isanti, ukuqhumisa isanti nge-Sa2.5 grade okanye ngaphezulu, isiphumo esingcono kakhulu sifumaneka ngokuqhumisa isanti nge-46-mesh corundum (i-white corundum).

Izixhobo zokugquma: Zicocekile kwaye zomile, akufuneki zichukumise amanzi okanye ezinye izinto, kungenjalo ziya kuchaphazela ukusebenza kakuhle kwengubo okanye ziyenze ingasetyenziswa.

2. Indlela yokwaleka

Ukutshiza: Futha kubushushu begumbi. Kucetyiswa ukuba ubukhulu bokutshiza bube malunga ne-50 ukuya kwi-100 microns. Emva kokutshiza ngesanti, coca umsebenzi kakuhle nge-anhydrous ethanol uze uyomise ngomoya ocinezelweyo. Emva koko, inkqubo yokutshiza ingaqalisa.

3. Izixhobo zokugquma

Isixhobo sokugquma: Isibhamu sokutshiza (ububanzi obuyi-1.0). Isiphumo se-atomization sesibhamu sokutshiza esincinci singcono, kwaye isiphumo sokutshiza singcono. Kufuneka i-air compressor kunye ne-air filter.

4. Unyango lokwaleka

Ingaphola ngokwendalo kwaye ingashiywa ngaphezulu kweeyure ezili-12 (yomisa umphezulu kwiiyure ezi-2, yomise ngokupheleleyo kwiiyure ezingama-24, kwaye i-ceramicization kwiintsuku ezi-7). Okanye yibeke kwi-oven ukuze yome ngokwendalo imizuzu engama-30, uze uyibhake kwi-150 degrees eminye imizuzu engama-30 ukuze yome ngokukhawuleza.

Phawula

1. Ngokuxhomekeke kwiimeko ezahlukeneyo zokusebenza, isicelo sokugquma kunye nenkqubo yokunyanga ukugquma ekhankanyiweyo apha ngasentla zingasetyenziswa kabini (ukuphinda yonke inkqubo njengesicelo esinye) okanye ngaphezulu kwesibini ukuze kufezekiswe isiphumo esizinzileyo esihambelana neemeko zokusebenza zokwenyani.

2. Musa ukuyithulula i-nano-coating engasetyenziswanga evela kwiphakheji yokuqala. Yihluze ngelaphu lesihluzi esinee-mesh ezingama-200 uze uyigcine yodwa. Ingasetyenziswa kamva.

Ukugcinwa kwemveliso: Gcina kwisikhongozeli esivaliweyo kude nokukhanya. Gcina kwindawo ephakathi kwe-5℃ ukuya kwi-30℃. Ixesha lokugcinwa kwe-nano coating ziinyanga ezi-6. Kucetyiswa ukuba uyisebenzise ingadlulanga inyanga emva kokuvulwa ukuze ufumane iziphumo ezingcono. (Ii-nanoparticles zinamandla aphezulu omphezulu, zisebenza kakhulu kwaye zinobunzima bokuxinana.) Phantsi kwesenzo se-dispersants kunye nonyango lomphezulu, ii-nanoparticles zihlala zizinzile ixesha elithile.

Amanqaku Akhethekileyo

1. Olu phawu lwe-nano-coating lolokusetyenziswa ngqo kuphela. Musa ukongeza ezinye izinto (ingakumbi amanzi), kungenjalo luya kuchaphazela kakhulu ukusebenza kakuhle kophawu lwe-nano-coating kwaye lude lubangele ukuba lukrazulwe ngokukhawuleza.

2. Ukhuseleko lomqhubi: Njengokhuseleko ngexesha lokufaka iipeyinti eziqhelekileyo, gcina kude namalangatye avulekileyo, ii-arcs zombane kunye neentlantsi zombane ngexesha lenkqubo yokupeyinta. Ukuze ufumane iinkcukacha ezithile, nceda ujonge kwi-Reference ye-MSDS yale mveliso.

Yahlukile kuYoucai

1. Uzinzo lobuchwephesha

Emva kovavanyo oluqatha, inkqubo yeteknoloji ye-nanocomposite ceramic ye-aerospace ihlala izinzile phantsi kweemeko ezinzima, imelana namaqondo obushushu aphezulu, ukutshayiswa kobushushu kunye nokugqwala kweekhemikhali.

2. Itekhnoloji yokusasazwa kweNano

Inkqubo yokusasazwa eyahlukileyo iqinisekisa ukuba ii-nanoparticles zisasazwa ngokulinganayo kwi-coating, ziphepha ukuhlangana. Unyango olusebenzayo lwe-interface luphucula ukubopha phakathi kwee-particles, luphucula amandla okubopha phakathi kwe-coating kunye ne-substrate kunye nokusebenza ngokubanzi.

3. Ukulawulwa kokwaleka

Iifomyula ezichanekileyo kunye neendlela ezidityanisiweyo zenza ukuba ukusebenza kwengubo kube nokulungelelaniswa, njengobunzima, ukumelana nokuguguleka kunye nokuzinza kobushushu, okuhlangabezana neemfuno zezicelo ezahlukeneyo.

4. Iimpawu zesakhiwo se-Micro-nano:

Iinxalenye ze-ceramic ezi-nanocomposite zisonga iinxalenye ze-micrometer, zizalise izikhewu, zenze uqweqwe oluxineneyo, kwaye zonyusa ubuncinci kunye nokumelana nokugqwala. Okwangoku, iinxalenye ze-nano zingena kumphezulu we-substrate, zenze i-interphase yesinyithi-ye-ceramic, eyonyusa amandla okubopha kunye namandla ngokubanzi.

Umgaqo wophando nophuhliso

1. Ingxaki yokufanisa ukwanda kobushushu: Ii-coefficients zokwanda kobushushu besinyithi kunye nezinto zeseramikhi zihlala zahluka ngexesha leenkqubo zokufudumeza nokupholisa. Oku kunokukhokelela ekwakhiweni kwee-microcracks kwi-coating ngexesha lenkqubo yokujikeleza kobushushu, okanye nokuxobuka. Ukujongana nale ngxaki, uYoucai uphuhlise izixhobo ezintsha zokugquma ezinomlinganiselo wokwanda kobushushu osondeleyo kulowo we-substrate yesinyithi, ngaloo ndlela kunciphisa uxinzelelo lobushushu.

2. Ukuxhathisa ukutshayiswa bubushushu kunye nokungcangcazela kobushushu: Xa uqweqwe lomphezulu wesinyithi lutshintsha ngokukhawuleza phakathi kobushushu obuphezulu nobuphantsi, kufuneka lukwazi ukumelana noxinzelelo lobushushu oluvelayo ngaphandle komonakalo. Oku kufuna ukuba uqweqwe lube nokumelana nokutshayiswa bubushushu okugqwesileyo. Ngokwenza ngcono ulwakhiwo lwe-microstructure yoqweqwe, njengokwandisa inani leendawo zokudibanisa izigaba kunye nokunciphisa ubungakanani bengqolowa, i-Youcai inokuphucula ukumelana kwayo nokutshayiswa bubushushu.

3. Amandla okubopha: Amandla okubopha phakathi kwengubo kunye ne-substrate yesinyithi abalulekile ekuzinzeni nasekuqineni kwexesha elide kwengubo. Ukuphucula amandla okubopha, uYoucai uzisa umaleko ophakathi okanye umaleko wokutshintsha phakathi kwengubo kunye ne-substrate ukuphucula ukumanzi kunye nokubopha kweekhemikhali phakathi kwezi zimbini.