I-Yc-8101a I-Porcelain Nano-composite Ceramic Coating enobushushu obuphezulu (Emnyama)

Izixhobo zemveliso kunye nenkangeleko

(Ukwaleka kweseramikhi okuneziqendu ezimbini)

YC-8101A-A:Ukwaleka kweCandelo A

YC-8101A-B: Iarhente yokunyanga yecandelo le-B

Imibala ye-YC-8101:okubonakalayo, obomvu, omthubi, oluhlaza okwesibhakabhaka, omhlophe, njl. Ukulungiswa kombala kungenziwa ngokweemfuno zabathengi

Isiseko esisebenzayo

Imiphezulu yeendawo ezahlukeneyo ezifana neepani ezinganamatheliyo inokwenziwa ngentsimbi, intsimbi ethambileyo, intsimbi yekhabhoni, intsimbi engatyiwayo, i-aluminium alloy, i-titanium alloy, intsimbi ye-alloy enobushushu obuphezulu, iglasi ye-microcrystalline, iiseramikhi, kunye nezinye ii-alloys.

Ubushushu obusebenzayo

- Ukumelana nobushushu obuphezulu yi-800℃, kwaye ubushushu bokusebenza bexesha elide bungaphakathi kwe-600℃. Ayikwazi ukumelana nokukhukuliseka ngqo ngamalangatye okanye ukuhamba kwegesi kubushushu obuphezulu.

- Ukumelana nobushushu kwengubo kuya kwahluka ngokuxhomekeke kukumelana nobushushu bezinto ezahlukeneyo. Iyamelana nokubanda kunye nobushushu kunye nokungcangcazela kobushushu.

Iimpawu zemveliso

- 1. Ii-nano-coatings zisekelwe emanzini kuphela, zikhuselekile, zinobuhlobo nokusingqongileyo kwaye azinabungozi.

- 2. Iiseramikhi ezidityanisiweyo nezincinci zifumana i-vitrification exineneyo negudileyo kubushushu obuphantsi be-250℃, nto leyo egcina amandla kwaye inomtsalane ngobuhle.

- 3. Ukumelana neekhemikhali: Ukumelana nobushushu, ukumelana ne-asidi, ukumelana ne-alkali, ubushushu, ukumelana nobushushu obuphezulu, kunye nokumelana neemveliso zeekhemikhali, njl.

- 4. Ingubo iyamelana namaqondo obushushu aphezulu kunye noxinzelelo lobushushu ngaphakathi kobukhulu obuthile (malunga ne-30 microns), kwaye inokumelana okuhle noxinzelelo lobushushu (iyamelana notshintsho lobushushu, kwaye ayiqhekeki okanye iqhekeke ngexesha lomsebenzi wengubo).

- 5. I-nano-inorganic coating ixinene kwaye inokusebenza okuzinzileyo kokugquma umbane, kunye ne-insulation imelana ne-voltage emalunga ne-1000 volts.

- 6. Inomoya oqinileyo nolungileyo wokuhambisa ubushushu kunye namandla agqwesileyo okubopha.

- 7. Ukuqina: 9H, ukumelana namalangatye avulekileyo kunye namaqondo obushushu aphezulu ukuya kuthi ga kwi-400 degrees, ukukhanya okuphezulu, kunye nokumelana nokuguguleka okuphezulu

Amasimi esicelo

1. Izixhobo zebhoyila, imibhobho, iivalvu, izitshintshi zobushushu, iiradiator;

2. Iglasi ye-microcrystalline, izixhobo kunye nezixhobo, izixhobo zonyango, izixhobo zamayeza, kunye nezixhobo ze-biological gene;

3. Izixhobo ezisebenzisa ubushushu obuphezulu kunye nezixhobo zesensor ezisebenzisa ubushushu obuphezulu;

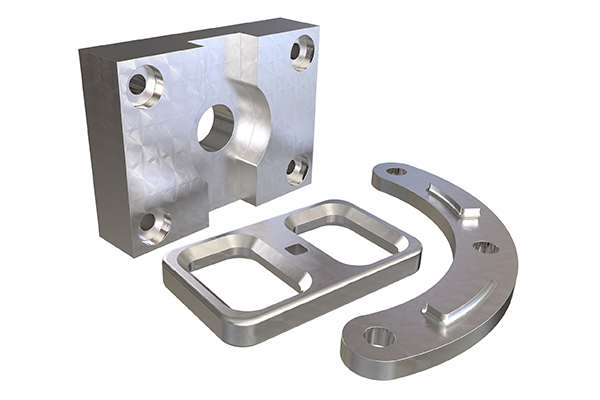

4. Imiphezulu yezixhobo zesinyithi, iimold, kunye nezixhobo zokuphosa;

5. Izinto zokufudumeza ngombane, iitanki, kunye neebhokisi;

6. Izixhobo zasekhaya ezincinci, izitya zasekhitshini, njl.

7. Izixhobo ezinobushushu obuphezulu kwimizi-mveliso yeekhemikhali nezesinyithi.

Indlela yokusetyenziswa

(Ukuqinisekisa iziphumo ezilungileyo, kucetyiswa ukuba uyisebenzise ngale ndlela ilandelayo)

1. Izinto ezimbini:Vala uze ulungise ngomlinganiselo wobunzima be-2:1 iiyure ezi-2 ukuya kwezi-3. Emva koko, i-coating ecociweyo ihluzwa ngesikrini sesihluzi se-400-mesh. I-coating ecociweyo iba yi-nano-composite ceramic coating egqityiweyo kwaye ibekelwe ecaleni ukuze isetyenziswe kamva. Ipeyinti eseleyo kufuneka isetyenziswe kwiiyure ezingama-24; kungenjalo, ukusebenza kwayo kuya kuncipha okanye kuqine.

2. Ukucoca izinto ezisisiseko:Ukususa amafutha kunye nokugqwala, ukurhawuzelela umphezulu kunye nokuqhumisa isanti, ukuqhumisa isanti nge-Sa2.5 grade okanye ngaphezulu, isiphumo esingcono kakhulu sifumaneka ngokuqhumisa isanti nge-46-mesh corundum (i-white corundum).

3. Ubushushu bokubhaka: 270℃ imizuzu engama-30 (Inganyangeka kubushushu begumbi. Ukusebenza kokuqala kuphantsi kancinci, kodwa inokubuyela esiqhelweni ngokuhamba kwexesha.)

4. Indlela yokwakha Ukutshiza:Indawo yokusebenza eza kutshizwa kufuneka itshiswe ibe malunga nama-40℃ ngaphambi kokuba itshizwe; kungenjalo, ukugoba okanye ukushwabana kungenzeka. Kucetyiswa ukuba ubukhulu bokutshiza bube ngaphakathi kwama-30 microns. Ingatshizwa kube kanye kuphela.

5. Unyango lwezixhobo zokugquma kunye nonyango lokugquma

Ukuphatha izixhobo zokugquma: Coca kakuhle nge-ethanol engenamanzi, yomise ngomoya ocinezelweyo uze uyigcine.

6. Unyango lokwaleka: Emva kokutshiza, yiyeke yome ngokwemvelo phezu komhlaba kangangemizuzu engama-30. Emva koko, yibeke kwi-oven eshushu ngama-250 degrees uze uyigcine ishushu imizuzu engama-30. Emva kokuyipholisa, yikhuphe.

Yahlukile kuYoucai

1. Uzinzo lobuchwephesha

Emva kovavanyo oluqatha, inkqubo yeteknoloji ye-nanocomposite ceramic ye-aerospace ihlala izinzile phantsi kweemeko ezinzima, imelana namaqondo obushushu aphezulu, ukutshayiswa kobushushu kunye nokugqwala kweekhemikhali.

2. Itekhnoloji yokusasazwa kweNano

Inkqubo yokusasazwa eyahlukileyo iqinisekisa ukuba ii-nanoparticles zisasazwa ngokulinganayo kwi-coating, ziphepha ukuhlangana. Unyango olusebenzayo lwe-interface luphucula ukubopha phakathi kwee-particles, luphucula amandla okubopha phakathi kwe-coating kunye ne-substrate kunye nokusebenza ngokubanzi.

3. Ukulawulwa kokwaleka

Iifomyula ezichanekileyo kunye neendlela ezidityanisiweyo zenza ukuba ukusebenza kwengubo kube nokulungelelaniswa, njengobunzima, ukumelana nokuguguleka kunye nokuzinza kobushushu, okuhlangabezana neemfuno zezicelo ezahlukeneyo.

4. Iimpawu zesakhiwo se-Micro-nano:

Iinxalenye ze-ceramic ezi-nanocomposite zisonga iinxalenye ze-micrometer, zizalise izikhewu, zenze uqweqwe oluxineneyo, kwaye zonyusa ubuncinci kunye nokumelana nokugqwala. Okwangoku, iinxalenye ze-nano zingena kumphezulu we-substrate, zenze i-interphase yesinyithi-ye-ceramic, eyonyusa amandla okubopha kunye namandla ngokubanzi.

Umgaqo wophando nophuhliso

1. Ingxaki yokufanisa ukwanda kobushushu:Ii-coefficients zokwandisa ubushushu bezinto zesinyithi neze-ceramic zihlala zahluka ngexesha leenkqubo zokufudumeza nokupholisa. Oku kunokukhokelela ekwakhiweni kwee-microcracks kwi-coating ngexesha lenkqubo yokujikeleza kobushushu, okanye nokuqhekeka. Ukujongana nale ngxaki, uYoucai uphuhlise izixhobo ezintsha zokugquma ezinomlinganiselo wokwandisa ubushushu osondeleyo kulowo we-substrate yesinyithi, ngaloo ndlela kunciphisa uxinzelelo lobushushu.

2. Ukumelana noxinzelelo lobushushu kunye nokungcangcazela kobushushu: Xa i-metal surface coating itshintsha ngokukhawuleza phakathi kwamaqondo obushushu aphezulu naphantsi, kufuneka ikwazi ukumelana noxinzelelo lobushushu oluvelayo ngaphandle komonakalo. Oku kufuna ukuba i-coating ibe nokumelana okuhle kakhulu nobushushu. Ngokwenza ngcono ulwakhiwo lwe-microstructure ye-coating, njengokwandisa inani le-phase interfaces kunye nokunciphisa ubungakanani be-grain, i-Youcai inokuphucula ukumelana kwayo nobushushu.

3. Amandla okubopha: Amandla okubopha phakathi kwengubo kunye ne-substrate yesinyithi abalulekile ekuzinzeni nasekuqineni kwexesha elide kwengubo. Ukuphucula amandla okubopha, uYoucai uzisa umaleko ophakathi okanye umaleko wokutshintsha phakathi kwengubo kunye ne-substrate ukuphucula ukumanzi kunye nokubopha kweekhemikhali phakathi kwezi zimbini.