Amagama angaqhelekanga emveliso

Ipeyinti ye-alkyd, i-alkyd top coat, ipeyinti ye-alkyd, ipeyinti ye-alkyd anticorrosive, i-alkyd anticorrosive top coat, i-alkyd magnetic top coat.

Iiparameter ezisisiseko

| Igama leMveliso yesiNgesi | I-Alkyd topcoat |

| Igama leMveliso yesiTshayina | I-Alkyd Magnetic Topcoat |

| Iimpahla Eziyingozi Inombolo | 33646 |

| Inombolo ye-UN | 1263 |

| Ukuguquguquka kwe-organic solvent | Imitha esemgangathweni engama-64³. |

| Uphawu | Imizobo kaJinhui |

| Inombolo yoMzekelo | C52-5 |

| Umbala | Umbala |

| Umlinganiselo wokuxuba | Icandelo elinye |

| Inkangeleko | Umphezulu ogudileyo |

Ukwakheka kwemveliso

Ipeyinti yeMagnetic yeAlkyd yipeyinti yemagnethi eyenziwe yi-alkyd resin, izongezo, ipetroli yesolvent enguNombolo 200 kunye nezinyibilikisi ezixutyiweyo, kunye ne-ejenti yokomisa.

Iimpawu

- Ukumelana nefilimu yokupeyinta kwitshokhwe, ukusebenza kakuhle kokukhusela, ukugcina ukukhanya kunye nombala, umbala oqaqambileyo, ukuqina okuhle.

- Inamathela kakuhle kwisinyithi nakumthi, kwaye inokumelana namanzi athile kunye nokumelana namanzi anetyuwa.

- Ifilimu yokupenda eqinileyo, ukutywina okuhle, ukusebenza kakuhle kokulwa nomhlwa, inokumelana nefuthe lomahluko wobushushu.

- Ukumelana kakuhle nemozulu, ukukhazimla kunye nobunzima.

- Umbala ophezulu, ukusebenza kakuhle kokusila.

- Ukunamathela okuqinileyo, iipropati ezilungileyo zoomatshini.

- Ubuchule bokuzalisa obuqinileyo.

- Ukusebenza kakuhle kolwakhiwo.

Iiparameter zobugcisa: GB/T 25251-2010

- Imeko kwisitya: akukho maqhuqhuva aqinileyo emva kokuxuba nokuxuba, kwimeko efanayo.

- Ubunzima: ≤40um (isalathisi esiqhelekileyo: GB/T6753.1-2007)

- Ukumelana namanzi anetyuwa: 3% NaCl, iiyure ezingama-48 ngaphandle kokuqhekeka, ukudumba okanye ukuxobuka (Isalathisi esiqhelekileyo: GB/T9274-88)

- Umxholo wezinto ezingaguqukiyo: ≥50% (isalathisi esiqhelekileyo: GB/T1725-2007)

- Ukumelana namanzi: iiyure ezi-8 ngaphandle kokuqhekeka, ukudumba okanye ukuxobuka (Isalathisi esiqhelekileyo: GB/T9274-88)

- Ixesha lokomisa: ukomisa umphezulu ≤ iiyure ezisi-8, ukomisa ngokwenene ≤ iiyure ezingama-24 (isalathisi esiqhelekileyo: GB/T1728-79)

Unyango lomphezulu

Unyango lwentsimbi yokuqhumisa isanti kumphezulu ukuya kwi-Sa2.5 grade, uburhabaxa bomphezulu buyi-30um-75um.

Izixhobo zombane ezihla ziye kwizinga le-St3.

Ukudibanisa inkundla yangaphambili

I-primer ye-alkyd, ipeyinti ephakathi ye-alkyd mica.

Iiparameter zokwakha

| Ubukhulu befilimu obucetyiswayo | 60-80um |

| Idosi yethiyori | malunga ne-120g/m² (isekelwe kwifilimu eyomileyo ye-35um, ngaphandle kokulahleka) |

| Inani elicetyiswayo leengubo | Iijasi ezi-2 ukuya kwezi-3 |

| Ubushushu bokugcina | -10~40℃ |

| Ubushushu bokwakha | 5~40℃. |

| Ixesha lovavanyo | iiyure ezi-6 |

| Indlela yokwakha | Ukuxubha, ukutshiza ngomoya, ukuqengqeleka kunokuba njalo. |

| Ikhefu lokwaleka | Ubushushu be-substrate ℃ 5-10 15-20 25-30 |

| Isithuba esifutshane h 48 24 12 | |

| Ixesha elide akufuneki lidlule iintsuku ezisi-7. | |

| Ubushushu be-substrate kufuneka bube ngaphezu kwe-3℃ ngaphezulu kombethe, xa ubushushu be-substrate buphantsi kwe-5℃, ifilimu yepeyinti ayizukunyangeka kwaye akufuneki yakhiwe. | |

Ukwakhiwa kwepeyinti

Emva kokuvula ibhere, kufuneka ixutywe ngokulinganayo, ishiywe ime, kwaye emva kokuba ivuthiwe imizuzu engama-30, yongeza ubungakanani obufanelekileyo be-thinner kwaye ulungelelanise i-viscosity yokwakha.

I-Diluent: i-diluent ekhethekileyo yochungechunge lwe-alkyd.

Ukutshiza okungenamoya: Ubungakanani bokuxutywa yi-0-5% (ngokomlinganiselo wobunzima bepeyinti), umlinganiselo we-nozzle yi-0.4mm-0.5mm, uxinzelelo lokutshiza yi-20MPa-25MPa (200kg/cm²-250kg/cm²).

Ukutshiza ngomoya: Ubungakanani bokuxutywa yi-10-15% (ngokomlinganiselo wobunzima bepeyinti), umlinganiselo womlomo yi-1.5mm-2.0mm, uxinzelelo lokutshiza yi-0.3MPa-0.4MPa (3kg/cm²-4kg/cm²).

Ingubo yerola: Ubungakanani bokuxutywa yi-5-10% (ngokomlinganiselo wobunzima bepeyinti).

Ukusetyenziswa

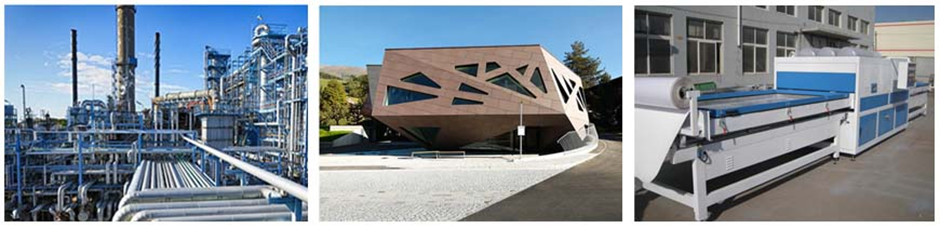

Ifanelekile kwiindawo zentsimbi, kwiindawo zoomatshini, kwiindawo zemibhobho, kwiindawo zezixhobo, kwiindawo zeenkuni, kwiindawo zentsimbi zangaphakathi nangaphandle kunye neendawo zeenkuni ukukhusela nokuhombisa, yipeyinti esetyenziswa ngokubanzi, esetyenziswa kakhulu kulwakhiwo, koomatshini, kwizithuthi nakwiindawo ezahlukeneyo zokuhombisa.

Phawula

Ukutshiza okomileyo kunokwenzeka ngexesha lonyaka oshushu:

- Kwixesha lobushushu obuphezulu, kulula ukomisa isitshizi, ukuze kuthintelwe isitshizi esomileyo, sinokulungiswa ngesitshizi esincinci de singatshisi.

- Le mveliso ifanele isetyenziswe ngabasebenzi abapeyintayo abaziingcali ngokwemiyalelo ekwiphakheji yemveliso okanye kule ncwadi yemiyalelo.

- Lonke ugquma kunye nokusetyenziswa kwale mveliso kufuneka kwenziwe ngokuhambelana nayo yonke imigaqo nemigangatho efanelekileyo yempilo, ukhuseleko kunye nokusingqongileyo.

- Ukuba unamathandabuzo malunga nokuba uza kuyisebenzisa na le mveliso okanye awuyisebenzisi, nceda unxibelelane nesebe lethu leenkonzo zobugcisa ukuze ufumane iinkcukacha.

Ukupakisha

Idrama engama-25kg.

Ukuthuthwa kunye nokugcinwa

Imveliso mayigcinwe kwindawo epholileyo nengena umoya, ithintelwe elangeni ngqo, kwaye ibekwe kude nemithombo yokutshisa, kude nemithombo yobushushu ekwindawo yokugcina impahla.

Xa kuthuthwa imveliso, kufuneka ithintelwe emvuleni, ekuchatshazelweni lilanga, kuthintelwe ukungqubana, kwaye kufuneka ithobele imigaqo efanelekileyo yesebe lezendlela.

Ukhuseleko loKhuseleko

Indawo yokwakha kufuneka ibe neendawo zokungenisa umoya ezifanelekileyo, kwaye abapeyinti kufuneka banxibe iiglasi, iiglavu, iimaski, njl.njl. ukunqanda ukudibana nolusu kunye nokuphefumla inkungu yepeyinti.

Umsi nomlilo akuvumelekanga ngokungqongqo kwindawo yokwakha.

Imibuzo Ebuzwa Rhoqo Ngumthengi

Ngaba kulula ukupenda ii-topcoats ezimhlophe nezikhanyayo emva kokusebenzisa i-Iron Red Anti-Rust?

A: Ii-enamel ze-alkyd eziqhelekileyo azinakusetyenziswa kwiindawo ezingentla.

Ngaba i-topcoat ingapeyintwa kwiplastiki, i-aluminium kunye neendawo ezifakwe i-galvanised?

A: Hayi, akulula, kufuneka ufake ezinye iingubo ezimbini ze-topcoat.

Ukwakhiwa kunye nokugcinwa kunye nokuthuthwa

1. Ngokwendlela eyakhiwe ngayo, sebenzisa i-alkyd thinner ukulungisa i-viscosity.

2. Ipeyinti ingabrashwa, igoqwe okanye itshizwe.

3. Ngaphambi kokwakha, kufuneka kususwe i-substrate yeoyile, ukungcola, uthuli kunye nomhlwa. Umswakama ongaphezulu kwe-85% akufuneki wakhiwe, abasebenzi bokwakha kufuneka baqinise ukhuseleko lwabo, banxibe izixhobo zokhuseleko ezifanelekileyo ukuthintela inkungu yepeyinti ephefumlwayo netshizwayo eluswini.

4. Imveliso mayibekwe kwindawo yokugcina izinto eyomileyo nepholileyo, ixesha layo lihlale iinyanga ezili-12. 5. Inkqubo yokugcina nokuthutha mayithintelwe ngokungqongqo ukungqubana, ilanga, imvula, kwaye ingabikho kwimithombo yomlilo.

Isalathiso solwakhiwo:

- Ukutshiza: uxinzelelo lomoya 0.3 ~ 0.4 Mpa viscosity 18 ~ 22 S / ipeyinti -4 iikomityi

- Ibhrashi: iyasebenza

- I-Diluent: i-diluent ekhethekileyo

- Ukusetyenziswa kwethiyori: 110 ~ 130g/square meter

- I-primer ehambelanayo: i-primer ye-alkyd ebomvu yentsimbi, ipeyinti yokulwa nomhlwa ye-alkyd ye-ferric, njl.

- Amanyathelo okhuseleko: Le mveliso inokutsha, igcinwa kwaye isetyenziswa kwiindawo zokwakha, qwalasela umoya, ukupholisa, kude nomlilo.

- Ukugcina: Gcina kwindawo epholileyo neyomileyo, ixesha elifanelekileyo lokugcina lonyaka omnye. Ukuba ixesha lokugcina lidlula unyaka omnye, imveliso ingasetyenziswa ukuba iyahlangabezana neemfuno emva kokuhlolwa.

- Ukutshiza, ukuxubha ibhrashi kungenziwa, kome okanye kome kubushushu begumbi (ubushushu bokomisa bungama-60-70 degrees)

- Ubukhulu bomaleko ngamnye yi-15-20 microns, owokuqala womile uze emva koko owesibini uwufake.

- Ingancitshiswa nge-turpentine kunye ne-200# petroleum solvent oil kunye ne-xylene kunye nezinye izinyibilikisi.

- Iimfuneko zepeyinti yemagnethi ye-alkyd: qala ngokufaka i-alkyd primer uze emva koko usebenzise i-alkyd putty ukwenza ukuba ithambe, uze ekugqibeleni ufake ipeyinti yemagnethi ye-alkyd.